Aircraft Strut Servicing - Here is a typical nose strut on a Beech Bonanza. Notice the Schrader valve (servicing valve) with the white cap in the center of the picture. This is where fluid and nitrogen are added to the strut.

This is a simple tool for removing and tightening the valve core in the Schrader valve. Before adding air or nitrogen to a strut that is low, it's a good idea to verify the core is tight.

Aircraft Strut Servicing

(You can buy this tool at an auto parts store, or even Walmart,) If one strut is more than 5″ then it would make sense to let a little pressure out. Also, sometimes the seals inside the strut get old and hard, and the strut does not move freely up and down.

In this case, it might help to install new seals in the bottom of the strut, and service with fresh hydraulic fluid and nitrogen. Yet another excellent podcast. Before listening to this, I had assumed that you always inflate the nose gear strut when you start seeing less chrome (on the trainer 172 I was instructed to look for "three fingers" of chrome during my pre-flight checks), and wasn't

t aware of the importance of the compression ratio between the static and compressed positions of the strut - The test of rocking the nose up and down to evaluate "springiness" and to also look for leaks makes sense and I'm glad that I am now

aware of the importance of knowing whether it is an issue of requiring more hydraulic fluid or nitrogen. You mentioned using compressed air or nitrogen at the beginning, and talked about nitrogen afterwards. What are your thoughts on using compressed air instead of nitrogen?

Thank you Lance! I really appreciate the feedback. I will definitely put your request on my list for a future episode. The Saratoga is a great airplane... we maintain a fair number of those in the shop where I work.

If you're ever in the Shenandoah Valley of Virginia, stop in and say hi! Thanks Eric, for all your feedback! I really appreciate knowing the episodes are helping airplane owners out there. So happy to hear your spars were clean.

The Archer is a great airplane... we've worked on a few of those over the years. I know the maintenance manual recommends the procedure you described. However, Avgas works much better than hydraulic fluid, to clean the strut shaft.

![Dvids - Images - Main Landing Gear Strut Repair [Image 3 Of 4]](https://d1ldvf68ux039x.cloudfront.net/thumbs/photos/2004/6187658/2000w_q95.jpg)

There is typically a snap ring and a scraper ring below the seal, so it's unlikely that the Avgas used on a cloth for cleaning, would even touch the rubber seal inside the strut. Another reason I don't like to use hydraulic fluid on the chrome shaft, is because of the potential for collecting dust and dirt.

Thanks for your thoughts! Thanks so much for a great podcast! I just discovered your 'cast a few days ago and have listened to several already. I own a 1986 Piper Archer, and just got through with the drama of pulling the fuel tanks and looking inside the wings.

Luckily my spars got a clean bill of health. I really wish I'd heard your episode about servicing struts before I attacked my nose strut with a nitrogen bottle and ended up with the nose pointing high in the air!

I'm really looking forward to catching up on the back episodes and hearing new ones. Thank you for the useful information. I have a PA28-161 and noticed one of the struts is higher (5+ inch) than the other (4 inch), both inside the recommended values 4.5 +- .5 but a 1.5 inch difference.

Mechanic showed me another PA28 that looks the same and explained it is a normal issue. He also pushed the higher wing to show me the strut compresses and returns to its position. I tested hard landings on that side and bounced a lot.

I was thinking, and correct me if wrong, to remove the strut cap and let some air/nitrogen release to see if the strut loses .5 inch at least. Do you think that is smart to do it or better adding more air to the shorter strut?

Thank you so much for your podcast on oleo struts. I have a Cessna 150 and was trying to see if I could add air instead of nitrogen. Doesn't appear to be leaking but with the winter weather it needs a little air/nitrogen now that it is Spring.

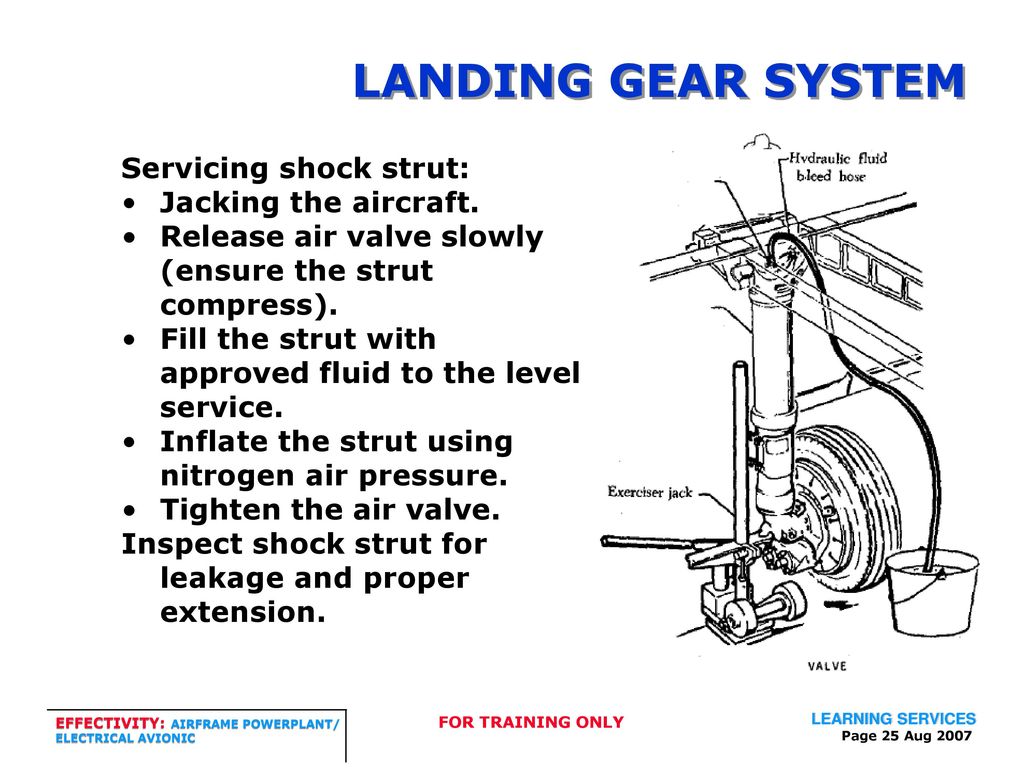

Thanks also for the safety warnings. I will tie the back down on the tarmac to take pressure off of it. Bogert Aviation's first strut service tool. Typically, the aircraft is placed on jacks. The SST is partially filled with fluid.

As the SST is attached to the strut, the pressure in the strut is released into the vented bottle. The strut is compressed and extended several times until the discharge is all fluid. With the strut compressed, remove the SST and service with high pressure air or nitrogen.

This is the basic strut service tool. Great value product. Although not a 'top of the line' tool, it still made servicing the strut a 'breeze'. Thank you. To improve it, I'm thinking of placing an o-ring over the tube, just under the lid, to prevent the tube from slipping out of the bottle too easily.

It happens! "2. Measure the extension levels on your struts and see if they meet the specs. While you do this, dampen a cloth with a little avgas, and clean the chrome shaft on the shock strut.

This will help prevent any dirt or other debris from getting in the sealing area as the shaft moves up and down inside the strut housing. And please... if you enjoy this podcast and want it to continue, let a few of your aviation friends know about it, and rate the podcast in iTunes.

(You can also find it in Stitcher, if you prefer that.) Thanks for the question about air vs. nitrogen. Nitrogen is considered the best option, since it is free of moisture. Compressed air will work fine if it is dry.

Also, nitrogen bottles typically hold approximately 2000 psi, whereas air compressors may be set to about 120 psi. So the nitrogen bottle is much more capable of adding a bit of pressure in a strut without putting the airplane on jacks.

If you want to learn more about an airplane strut, you can go to this link and read an excellent article by Mike Busch, with Savvy Aviator. I find his articles to be very educational and helpful.

aircraft strut servicing tool, strut rebuild service, aircraft strut servicing kit, aircraft nitrogen servicing equipment, aircraft nitrogen strut servicing regulator, aircraft strut service kit, shock strut landing gear, bogart tool