Aircraft Structural Technology - Hexagon's multidisciplinary simulation and analysis solutions have been widely used for aircraft structural analysis in the aerospace industry for more than 40 years. We have helped designers calculate the ideal aircraft structure design to handle the internal and external loads required to fly the aircraft aerodynamically and efficiently.

The Aircraft Structural Technology program is a sequence of courses that prepares students for careers in aircraft structures manufacture and repair. Learning opportunities develop academic, technical, and professional knowledge and skills required for job acquisition, retention, and advancement.

Aircraft Structural Technology

The program emphasizes a combination of aircraft structural theory and practical application necessary for successful employment. Program graduates receive an Aircraft Structural Technology diploma and are qualified as aircraft structural specialists. Aircraft structural technicians build new equipment and conduct repairs.

Program Overview

Manufacturing work is based on customer orders in a team assembly environment. Repair work is typically paid hourly and on an as needed basis, but training is needed for all types of aircraft (old and new) and is dependent on customers needing repairs.

An aircraft structure is a lightweight ecosystem made from circular frames, linear stringers and skin panels — either machined or formed from sheet metal. Each structural component must be manufactured and accurately assembled to become the safe modern aircraft we expect today.

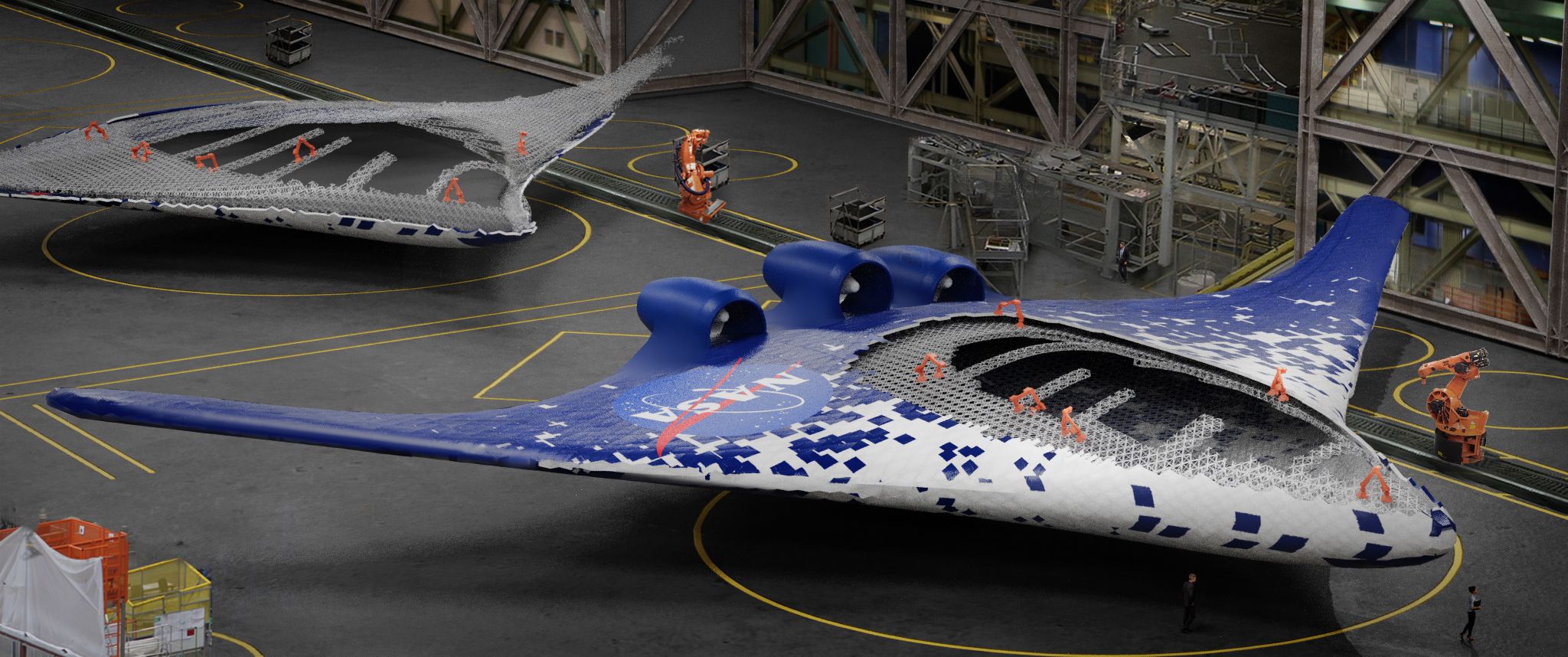

Metrology is also increasingly embedded in aircraft structure manufacturing plants, including the use of wireless machine tool probes for measurement within machining centers. Hexagon also offers a range of laser tracker-based robotic positioning solutions to help tool integrators and aerospace manufacturers automate workstations.

This enables aircraft manufacturers to ramp up aero-structure production by bringing speed and accuracy to the shop floor. From handheld 3D scanners to the world's most accurate laser trackers and the largest bridge and gantry CMMs, our portfolio offers metrology equipment for everything from micron measurement to surface quality checks on aircraft skin panels.

Entrance Requirements

With passenger traffic doubling and pressure to reduce ecological impact on the planet greater than ever, Hexagon has also developed tools for coupled simulation, lightweight composite material simulation and additive manufacturing. These simulation solutions have unique potential to help designers overcome major challenges and design structures for new generations of aircraft.

Education: A high school diploma or its equivalent is required for admission. Age: 16 years or older Placement: Achievement of appropriate scores on the college's placement test or submission of acceptable SAT or ACT scores. Provisional Admission accepted.

.switcher {font-family:Arial;font-size:12pt;text-align:left;cursor:pointer;overflow:hidden;width:173px;line-height:17px;} .switcher a {text-decoration:none;display:block;font-size:12pt;-webkit-box-sizing:content-box;-moz-box-sizing:content-box;box-sizing:content-box; } .switcher a img {vertical-align:middle;display:inline;border:0;padding:0;margin:0;opacity:0.8;} .switcher a:hover img {opacity:1;} .switcher .selected {background:#fff linear-gradient(180deg, #efefef 0%, #fff 70%);position:relative;z-index:9999;} .switcher .selected a {border:1px solid #ccc;color:#666;padding:3px 5px;width:161px;} .switcher .selected a:after {height:24px;display:inline-block;position:absolute;right:10px;width:15px;background-position:50%;background-size:11px;background-image:url(" data:image/svg+xml;utf8,"); background-repeat:no-repeat;content:""!important;transition:all .2s;}

Digital Transformation

.switcher .selected a.open:after {-webkit-transform: rotate(-180deg);transform:rotate(-180deg);} .switcher .selected a:hover {background:#fff} .switcher .option {position:relative;z-index:9998;border-left:1px solid #ccc;border-right:1px solid #ccc;border-bottom:1px solid #ccc;background-color:#eee;display :none;width:171px;max-height:198px;-webkit-box-sizing:content-box;-moz-box-sizing:content-box;box-sizing:content-box;overflow-y:auto;overflow -x:hidden;} .switcher .option a {color:#000;padding:3px 5px;} .switcher .option a:hover {background:#fff;} .switcher .option a.selected {background:#fff;} #selected_lang_name {float: none;}

.l_name {float: none !important;margin: 0;} .switcher .option::-webkit-scrollbar-track{-webkit-box-shadow:inset 0 0 3px rgba(0,0,0,0.3);border-radius:5px;background-color:#f5f5f5;} .switcher .option::-webkit-scrollbar {width:5px;} .switcher .option::-webkit-scrollbar-thumb {border-radius:5px;-webkit-box-shadow: inset 0 0 3px rgba(0,0,0,.3);background-color:#888;} Aircraft structural parts can include fuselage panels of over 40 square meters, as well as 10 or more meter structural spars and large assembly brackets.

Manufacturing such large components makes anticipating process deviation to reduce production time essential in the ramp up of structural components production for the aerospace industry. Shop-floor metrology tools, including non-contact inspection technologies, allow Hexagon customers to monitor the production process and manage the quality of the produced parts along their manufacturing workflow.

Our robust solutions are designed to function in challenging shop-floor conditions, such as dusty and noisy aircraft structure plants. Deploy Hexagon's sensor software systems to transform siloed and disconnected processes into an integrated, data-driven manufacturing ecosystem that captures and creates value across the product lifecycle, enabling new business models and automating workflows to become increasingly autonomous, efficient and sustainable.

airplane structure design, aircraft structural parts, aircraft frame structure, structures of an aircraft, airplane structures, aircraft structures pdf, plane frame structure, aircraft frame design