Aircraft Structures Mechanic Boeing - Current Boeing employees working in Puget Sound and Portland must submit an Employee Request Transfer (ERT) to be considered in the eligible candidate pool. Resumes of current Puget Sound Boeing employees submitted via Careers at Boeing will not be considered.

Boeing continues its modernization of the avionics systems in providing a new Mission Display Processor (MDP), new electronics for the head-up display, new VHF radios, a new surveillance capability called ADS-B Out, and further capability block upgrades.

Aircraft Structures Mechanic Boeing

As an Aircraft Structures Mechanic you will work within a final assembly/fabrication environment by drawing on knowledge acquired from training and certification classes to complete your daily assigned work. By interpreting drawings and reading/comprehending work instructions you will be responsible for identifying your work (task) location on the airplane/part/tooling and identifying all required hand tools, parts and equipment to accomplish defect-free work.

Avionics Component Integration Avci

The Boeing Company also provides eligible employees with an opportunity to enroll in a variety of benefit programs, generally including health insurance, flexible spending accounts, health savings accounts, retirement savings plans, life and disability insurance programs, and a number of programs that provide for

both paid and unpaid time away from work. To make training more relevant to modern day fighters, Boeing upgraded 466 of the advanced-jet training aircraft with a modernized cockpit, featuring a head-up display, up-front control panels, multifunctional displays, hands-on throttle and stick, and integrated

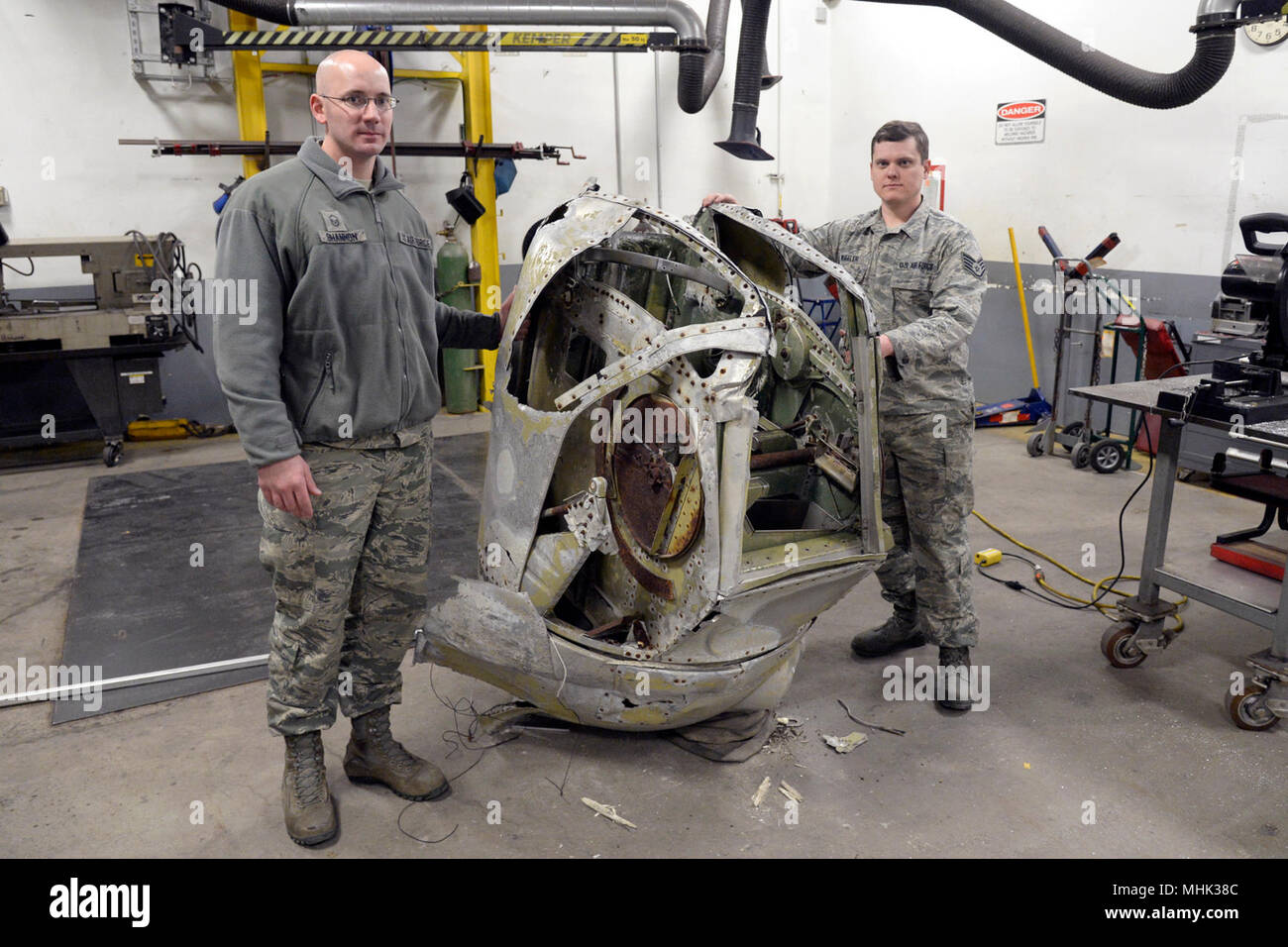

global positioning system. With 30 percent of lifecycle costs going to the purchase of a platform, the remaining 70 percent of sustainment costs is where Boeing's maintenance and modernization of aircraft drives affordability for customers. Extending the life of an aircraft is one of the many things that Boeing's engineering team does every day, 24x7, so customers meet their readiness needs.

The F/A-18 Super Hornet is a twin-engine, supersonic, all weather multirole fighter jet that is capable of landing and taking off from an aircraft carrier. Every Super Hornet has been delivered on cost and on schedule.

Avionics Upgrade Program Aup

Integrating new, advanced technologies that enable mission readiness is a cornerstone of the services and support Boeing provides to our military customers each and every day. From providing scheduled maintenance operations or upgrading an avionics system to trouble-shooting a mechanical issue or repainting a livery, we are committed to providing you best-in-class service.

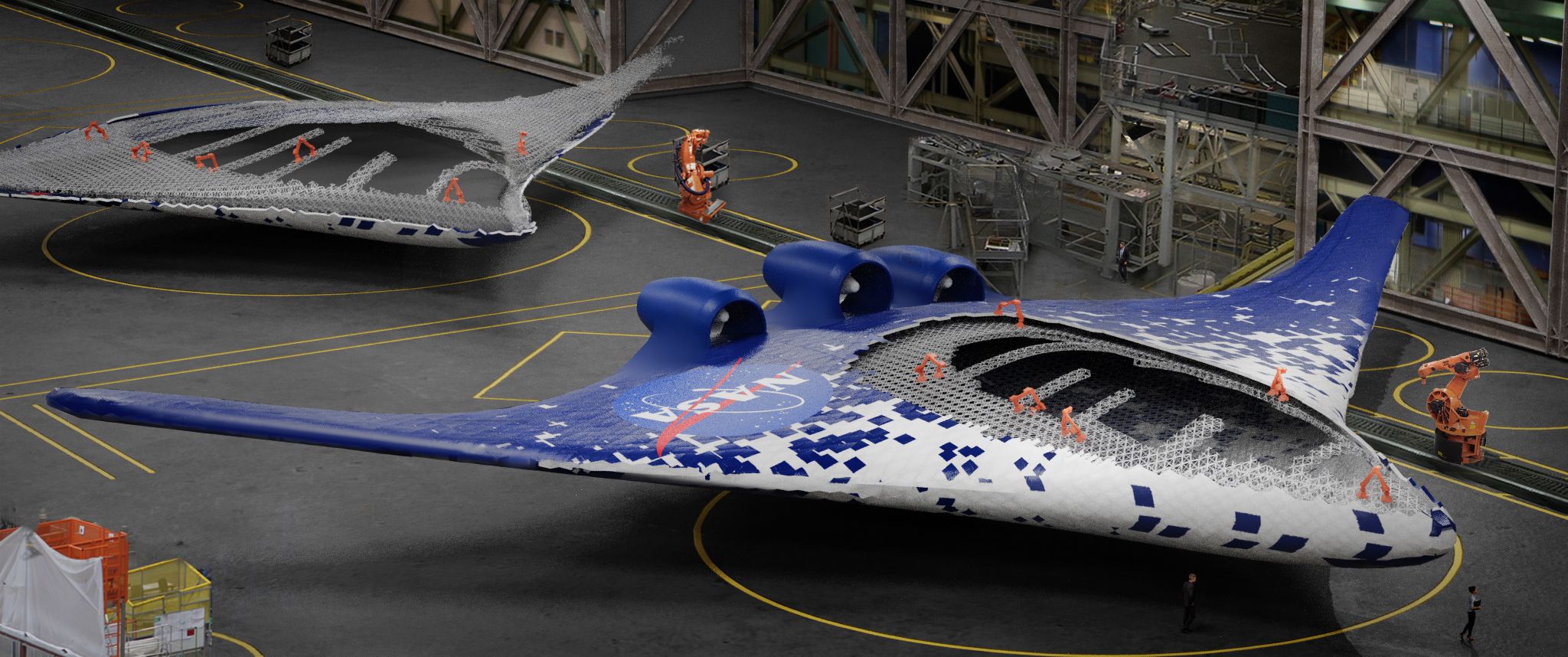

At Boeing, we innovate and collaborate to make the world a better place. From the seabed to outer space, you can contribute to work that matters with a company where diversity, equity and inclusion are shared values.

We're committed to fostering an environment for every teammate that's welcoming, respectful and inclusive, with great opportunities for professional growth. Find your future with us. On the F-22, Boeing was responsible for the avionics integration, seventy percent of the mission software as well as the life support and fire protection systems.

Also, Boeing has prime responsibility for radar system and power supplies development, production, and testing. Training on the F-22 simulator now includes Boeing's Constant Resolution Visual System, or CRVS — a high resolution, immersive training environment.

Built For Superiority

The standard CRVS provides constant 20/40 visual acuity over the entire 360-degree field of view. Boeing is an Equal Opportunity Employer. Employment decisions are made without regard to race, color, religion, national origin, gender, sexual orientation, gender identity, age, physical or mental disability, genetic factors, military/veteran status or other characteristics protected by law.

The Boeing Company is seeking an Aircraft Structures Mechanic to join our teams supporting Boeing Commercial Airplanes in Renton or Everett, WA. This is an exciting opportunity to assemble and install components, wiring and equipment for a critical structural assembly of an aircraft.

Boeing teamed with Lockheed Martin to develop and build the F-22, an extremely advanced tactical fighter that combines stealth, integrated avionics and maneuverability. Boeing built the wings and aft fuselage, including the structures necessary for engine and nozzle installations and development of the auxiliary power units.

Helping Our Customers Meet The Demands Of Their Mission Day And Night

boeing aircraft mechanic jobs, aircraft structure mechanic jobs, in tank mechanic boeing, boeing a&p mechanic salary, boeing mechanic jobs, boeing mechanic salary, aircraft structures mechanic job description, mechanical engineering boeing

![Dvids - Images - Main Landing Gear Strut Repair [Image 3 Of 4]](https://d1ldvf68ux039x.cloudfront.net/thumbs/photos/2004/6187658/2000w_q95.jpg)