Aircraft Structural Maintenance Afsc - Frequent. TDY's happen semi-annually, & full on deployments for F-22 troops may occur annually. These deployments are popular, so it is usually first come first served. You need to decide if you want to deploy BEFORE the tasking comes out, because available slots will fill up if you take too long to make up your mind.

Three volumes, pertaining to standard MX practices, Sheet Metal (Most of which you won't use), & LO processes. You will have ample time during work hours to knock these out depending on who your crew lead is.

Aircraft Structural Maintenance Afsc

Limited. There are only about 8 LO bases (This may change in the future, depending on the F-35's development), of which 3 are off limits to new personnel. The F-22 bases are Tyndall in Northern Florida (About two hours away from the Tech School), Langley in Southern Virginia, Hickam in Hawaii, & Elmendorf in Alaska.

Career Development Courses Cdcs

The B-2 is only stationed at Whiteman in Missouri, & the F-35 is currently located at Hill in Utah, Eglin in Northern Florida, & Edwards in California near Vegas, but there is talk of expanding, & currently Eielson Alaska is slated

to receive 35's, & rumors of some heading to England. A point that is impossible not to mention is the danger associated with the job. As an LO technician, you will be in contact with dozens of dangerous chemicals.

Cancer is a huge concern, & it isn’t even the scariest of the dangers present. Because the job is new in relation to other AFSC’s, it isn’t completely clear what the long term health effects will be on technicians, but it is imperative that you wear proper PPE at all times when in the LO environment.

Shifts with the wind. On a busy day, there will barely be time for lunch, & the very next day, you may have upwards of four hours available to you. There is an unspoken expectation that if you have the ability to help out, even on a jet that isn't assigned to you, you should, but it is possible that the entire hangar will be clear of work for an hour or two.

Base Choices

There will be time, but you shouldn't plan your schedule on expecting it. You must pass the basic Secret Clearance, but when you arrive at your first base, you will be further examined before you gain access to any of the sensitive information that makes up LO.

It is not required that you pass this additional exam, and indeed many people opt not to apply for it, but it slightly limits your usefulness to not have the special clearance. You repair the stealth coatings on stealth aircraft such as the F-22, F-35, & B-2.

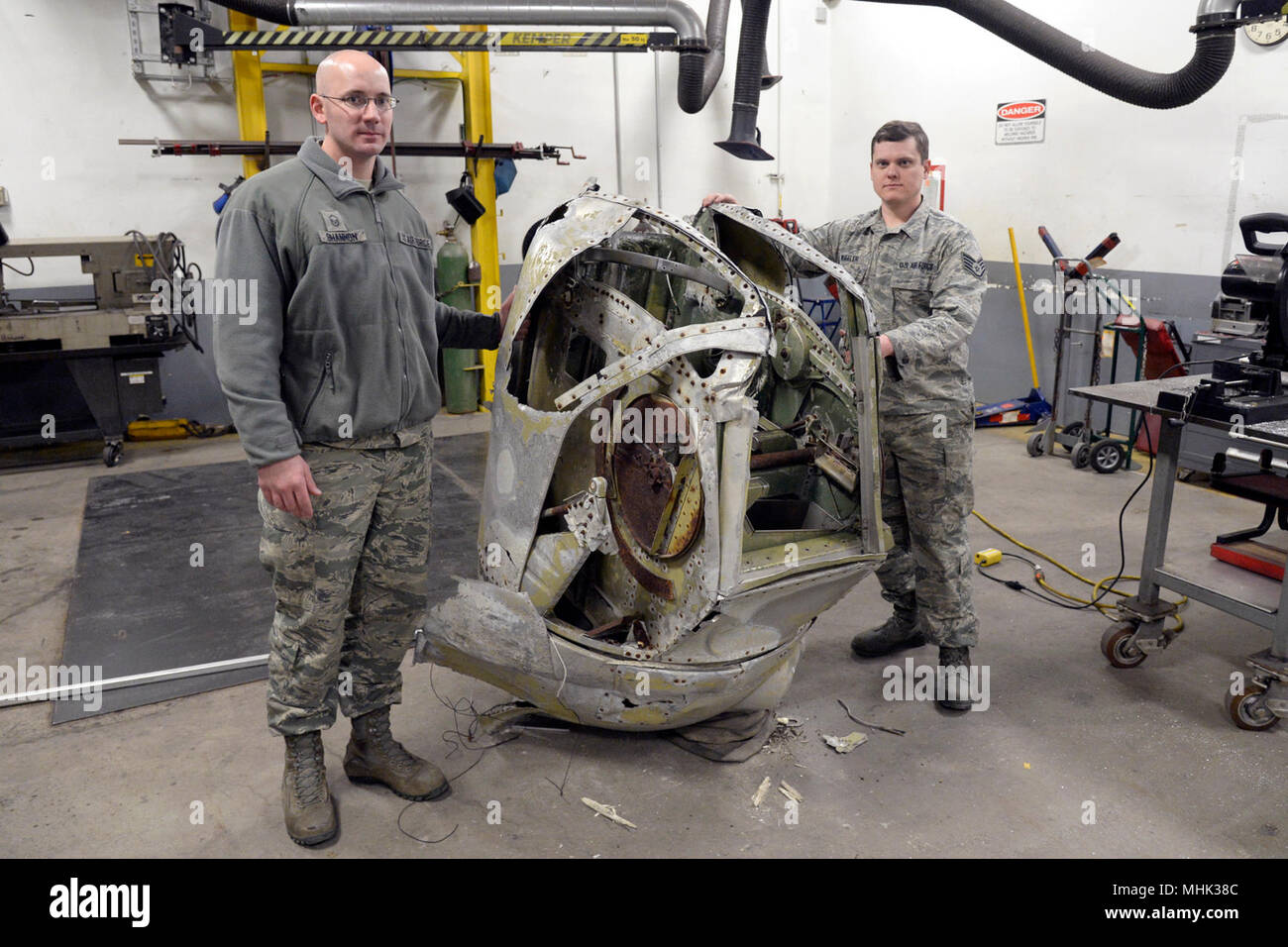

The nature of the job is sensitive, but most repairs are done through a process of sanding, painting via spray & brush, & applying special materials to dampen RADAR returns. Additionally, you will be required to know a limited amount of skills related to sheet metal;

the main ones being removing stuck fasteners, replacing nutplates, & shooting rivets. With time you will learn the more specialized repairs such as composite structure repair, evaluations of coatings, & other classified items. Attention to detail is paramount to the successful completion of the job.

What An Average Day Is Like

You will be desirable to many employers if you have a solid knowledge of Composite repair & fabrication. If not, usually your relevant experience is confined to working on LO aircraft as a civilian for Lockheed Martin.

It pays well, but for people who don't enjoy the job, they may not see this as an attractive option. Advances in technology allow us to carry out aircraft missions without being detected, but it takes a skilled human touch to ensure the technology is properly in place.

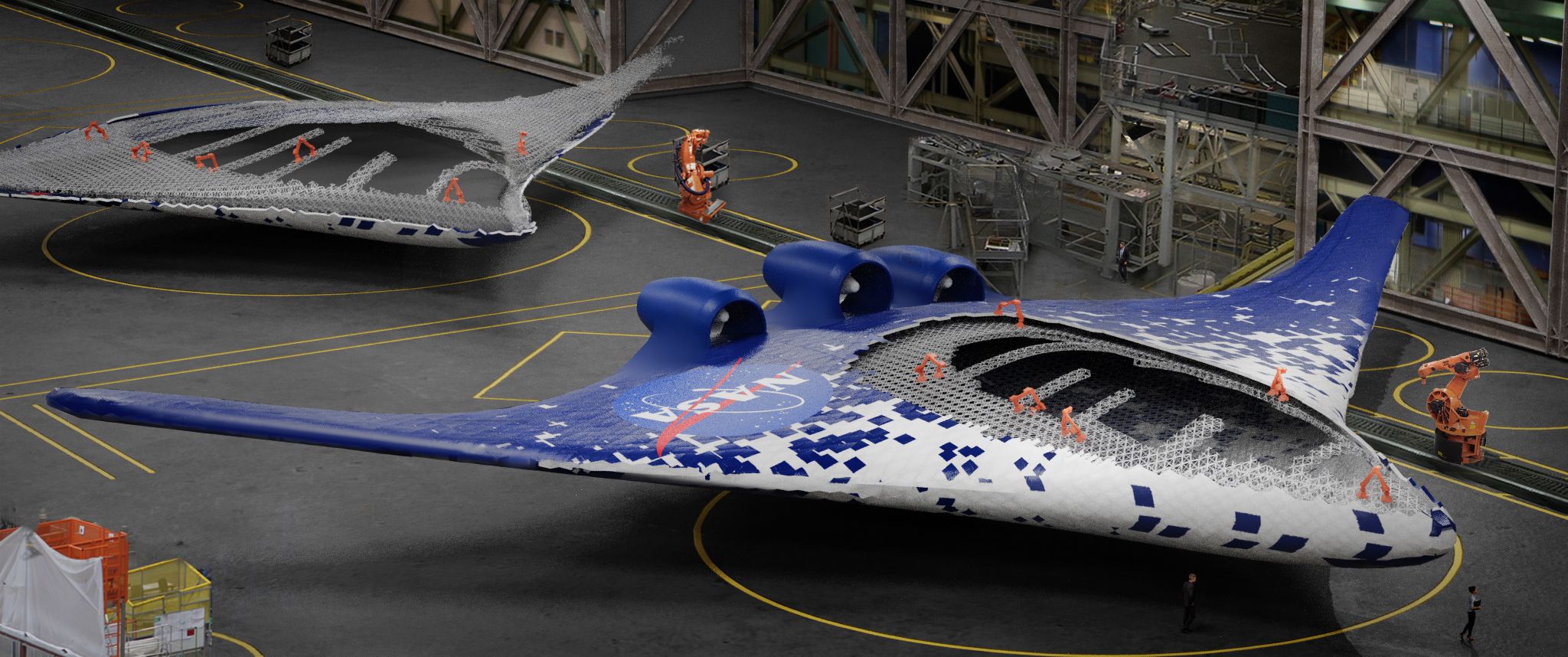

It’s the job of Low Observable Aircraft Structural Maintenance specialists to design, fabricate and modify unique metals and bonded materials that create the stealth effect. From the first application to repairing structural damage, these experts make sure aircraft can continuously complete their missions completely undetected.

Because of the massive responsibility of the LO shop, there are upwards of a hundred personnel at a single LO base to ensure that 24/7 operations are able to take place. Because of this, it’s easy to find a niche of people that you will fit in with, but by nature of the flight line, you’ll almost assuredly be on a shift with at least one person you find intolerable.

Ability To Do Schoolwork

MX is a dirty career field, but the camaraderie is strong. Strong language is to be expected, & people who are more sensitive will find their first few weeks difficult, but adapting is typical. Mostly you will be viewed by your ability to complete the job well & quickly, with your personality being scored second.

Evaluates, installs, removes and repairs low observable (LO) coatings. Designs, repairs, modifies and manufactures aircraft, metal, plastic, composite, advanced composite, LO, and bonded structural parts and components. Applies preservative treatments to aircraft, aerospace ground equipment (AGE), and support equipment (SE).

Knowledge. Knowledge is mandatory of: metal repair and fabrication processes; composition of metals and machinable materials; welding specifications; metal tempering; forging mechanical drawings; use of precision measuring devices and tools; metal fabricating by oxyacetylene, metallic arc, and inert gas shielded arc;

operation and capacity of metal working and welding equipment; use and fabrication of layout and fixture devices; safety codes and practices regarding equipment and supplies; hazards of explosive gases, hazardous rays, and fumes; and proper handling, use, and disposal of hazardous waste and materials. Education.

Security Clearance

For entry into this specialty, completion of high school with courses in shop mathematics, metal working, or mechanical drawing is desirable. For award of AFSC 2A731, completion of a basic aircraft metals technology course is mandatory. For award of AFSC 2A771, completion of the craftsman aircraft metals technology course is mandatory. Experience.

The following experience is mandatory for award of the AFSC indicated: (Note: See Explanation of Air Force Specialty Codes). 2A751. Qualification in and possession of AFSC 2A731. Also, experience in functions such as gas and electric welding, boring, milling, shaping, grinding metal, or using precision measuring devices. 2A771.

Qualification in and possession of AFSC 2A751. Also, experience performing or supervising functions dealing with welding, using precision measuring devices, and machining.Other. The following are mandatory as indicated: For entry, award, and retention of AFSCs 2A711/31/51/71, normal depth perception as defined in AFI 48-123, Medical Examination, and Standards.

The area itself is interesting; the Air Force is the minority on NAS Pensacola, as most personnel on the base are Navy & Marines training in their various roles as aircraft maintainers. Although some friction exists between the AF & the other two branches, usually inter-service interactions are friendly.

Detailed Description

It never fails though that they WILL be condescending during PT though. Three Months at NAS Pensacola in Northern Florida with the 359th TRS DET 1. You'll depart from Lackland Airport & arrive at a civilian airport in Pensacola, where you will be shuttled to the base.

There are unofficially two stages of Tech School. “The Lower Blocks”, where you will be taught safety, history of LO Technology, standard aircraft maintenance practices, & basic sheet metal. “The Upper Blocks” is where you will learn more LO specific tasks, such as composite repairs, coating application, & other various LO tasks.

2a735 air force, aircraft structural maintenance tech school, air force structural afsc, 2a733 air force, aircraft structural maintenance 2a7x3, 2a753 afsc, aircraft structural maintenance air force, afsc 2a733